How glasses are created (The step-by-step eyewear design process)

Have you ever wondered how we put new eyewear collections together season after season? Where do we get our ideas from? How do we decide on a frame’s look? How do we ensure a perfect fit? We reveal here how we create our new eyewear designs for you.

One thing’s for certain: the development of attractive, top performance eyewear demands the full collaboration and the talents of both the design and the product management teams. It’s their expertise, creativity, passion and love that enable the creation of world-class eyewear products.

STEP 1 – INSPIRATIONS ARE EVERYWHERE

In this stimulating first stage, mood boards are made up. These visual collages display upcoming design directions, taking the latest fashion world forecasts to identify hot trends in shape, colour, topics and concepts. But fashion isn’t the only inspiration. Just walking around with an open mind leads to discoveries from which new ideas can be drawn. Whether it’s architecture, art, certain colour combinations or simply nature, it’s all food for our creative appetites. With the presentation of all these stimulating ideas and fresh trends, a passionate brainstorming session kicks off. The most popular highlights of this discussion form the basis for our new creations.

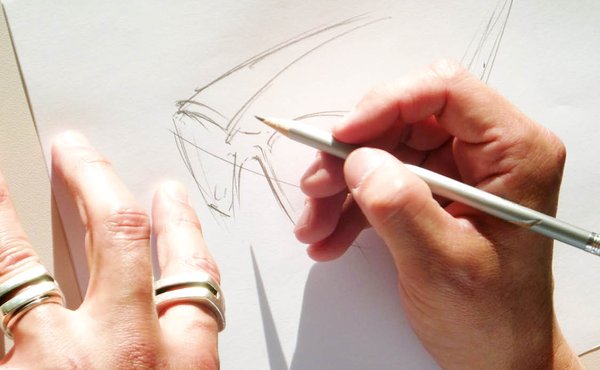

STEP 2 – THE ART OF DESIGN

Our designers put the first concepts on paper. Ideas are exchanged and discussed, decorative elements are worked out and everyone involved decides on colour nuances and combinations. The resulting product design drawings, which in addition to the look also feature information on frame materials and dimensions, are carefully examined again by the entire team. The drawings that everyone is most excited about are passed on to our factories, where experienced engineers check design feasibility before proceeding to prototyping.

STEP 3 – CRAFTSMANSHIP IN PERFECTION

True craftsmanship is required when manufacturing the prototypes. At this stage, as there are no moulds available, each prototype has to be made by hand, requiring great expertise and attention to detail. During this process, the number of steps required and the complexity involved in final production are ascertained.

STEP 4 – STRICT TECHNICAL INSPECTION

Once the prototypes are finished, each one of them has to go through strict technical tests. Our technical specialists check the individual frame components for material strength, stability and density, among other things. Quality plays the most important role for us and this control step is one of many that ensure that the new eyewear frames meet our high quality standards.

STEP 5 – QUALIFICATION FOR FINISHING

As soon as the frame prototypes land on the table of the product team, they are checked for appearance, feel and fit. Only the best frames are admitted for a further round of fine-tuning, where the latest changes are discussed and determined. The production samples are now completed with a great deal of passion and attention to detail and the moulds are produced in turn using extensive, manual know-how.

STEP 6 – THE BEST MOMENT: THE FINISHED PRODUCT TO TOUCH

After final technical tests, the necessary fine-tuning and various analyses, the production wheels are set in motion. The team eagerly awaits the first finished samples.

These samples are tested according to CE guidelines before they are launched on the market. At CHARMANT, in addition to CE tests, we also carry out self-imposed quality tests to ensure the high quality of our eyeglass frames.

Finally the moment arrives! Designers and product managers describe it as “THE” moment when finished frame samples can be seen and handled on the table in front of them. This is a big highlight for everyone involved and the reward for what they have created together as a team.

And then of course we all hope that our glasses will delight you as well! :-)